Plastic Injection Molding Services

Abstract. Mold (cetakan) merupakan perkakas pada proses injection molding untuk membuat produk dari plastik. Akibat penggunaan selama proses produksinya, mold ini dapat mengalami kerusakan yang.

Plastic Injection Molding Rajawali Multiplastindo Jaya (RMJ)

Injeksi molding. Pencetakan suntik atau pengacuan suntik ( Inggris: injection molding) adalah metode pembentukan material termoplastik di mana material yang meleleh karena pemanasan disuntikkan oleh plunger ke dalam cetakan yang didinginkan oleh air sehingga mengeras. Meskipun banyak ragam dari proses dasar ini, 90 persen injection molding.

Plastic Injection Molding Omega Plastics, Inc.

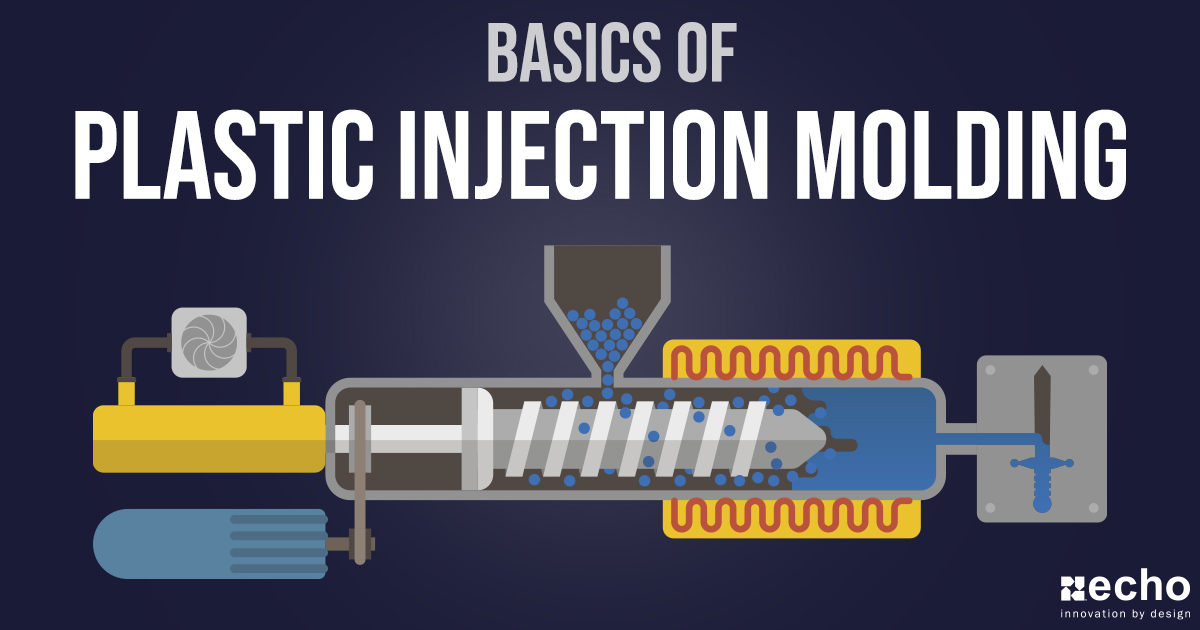

Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing. The process of injection molding is divided into 6.

Plastic Injection Molding Injectionmolding Vietnam, your manufacturer and fabrication partner

Solutions. Reduce the thick wall size of the mold material and control the adjacent wall thickness. Increase holding time and pressure. Increase the cooling time. 3. Weld Lines. Weld lines are plastic molded part defects that cause a convergence of molten material on the surface of your part.

Plastic Injection Ayberksan Plastic Mold Industry

Injection Stretch Blow Moulding (ISBM) happens in 2 Stages on a rotating platform, similar to IBM. In the case of ISBM, the process is oriented vertically. Plastic is first extruded, meaning the pellets are fed into an extruder with a rotating screw, which, as it spins, created enough friction to melt the plastic pellets. Stage 1:

Plastic Injection Molding Process Guide 2019 Full Process Explained

Plastic injection molding is better than 3D printing for larger production runs, stronger parts, faster production, and a larger variety of materials that can be used, including fillers. Because injection molding's manufacturing process simply involves the injection and cooling of plastic, a part can be formed within a few minutes at the most.

Plastic Injection Moulding — B&C Plastics

Design of Mold Venting System. 1. Mold Venting Design Points. The mold vent should be designed on the cavity side of the parting surface, in order to facilitate mold manufacturing and cleaning. Try to set it at the end of the material flow and the thicker section of the plastic part. The venting direction should not face the operator, but.

Injection Molding Machines Types, Costs, How To Choose The Best Machine For Plastic Injection

Sprue (manufacturing) A sprue is a large diameter vertical channel through which liquid material is introduced into a mold. It connects the pouring basin to the runner. In many cases it controls the flow of material into the mold. During casting or molding, the material in the sprue will solidify and need to be removed from the finished part.

[eBook] An Introduction to Plastic Injection Molding fully revised & expanded for 2020 The

TUGAS PROSES MANUFAKTUR II PLASTIC INJECTION PROSES Plastic Injection Proses Pendahuluan Benda plastik hampir kita temukan di semua tempat, mulai dari bungkus makanan, peralatan elektronik, mobil, motor, peralatan rumah tangga dan sebagainya.. 2. bagian besar mesin plastic injection 2. molding unit pada molding unit sebenarnya adalah bagian.

Plastic Injection Molding Definitions and Benefits of Using It TechBullion

In layman's terms, injection molding boils down to four simple steps: Melt material. Inject the molten material into a mold. Let the molten material cool to a solid-state. Remove the hardened material from the mold. But we can't talk about the injection molding process without discussing the injection molding machine.

Understanding Plastic Injection Molding Volumes The Rodon Group®

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one. 13 Jul 2023. Getting the Most Out of Injection Molding Simulation Multiple speakers at Molding 2023 will address the ways simulation can.

The Process of Plastic Injection Moulding Protomould Plastics

In multi-cavity injection mold, Molten plastic flow balancing is a challenging task. Three-Plate Mold. Three plate injection mold consists of two parting planes and mold splits into three sections. Therefore runners and components can be located on different parting planes. In three plate molds, the runner is ejected separately to the molded part.

9 Advantages of Plastic Injection Molding Altitude Branding

Cara kerja Injeksi Plastik (Plastic Injection Molding), Mesin Injeksi Plastik Vertical & Horizontal. Menutup Cetakan, Membuka Cetakan / Moulding Part Robot.. Istilah Mold dalam dunia Injeksi Plastik adalah cetakan untuk Proses Injeksi Plastik. Mold itu sendiri terdiri dari 2 bagian besar yaitu sisi "Core" dan sisi "Cavity".

Basics of Plastic Injection Molding Echo Supply

Bill details the key engineering principles underlying plastic injection molding. He describes its history and, then, reveals the intricate details of the p.

This is the Best Explanation of Plastic Injection Molding That You've Ever Seen SolidSmack

Plastic injection molding is the most commonly used manufacturing process for the production of small, medium, and large-sized plastic parts. The process utilizes an injection molding machine, raw plastic material, and a mold. The plastic is melted to molten heat in the machine and then injected into the mold, where it cools and solidifies into.

Five key benefits of plastic injection moulding

Injection molding is a complex manufacturing process. Using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a metal mold that's fitted into the machine. Plastic injection molding is the most widely used components manufacturing process for a variety of reasons, including: Flexibility.